Printing

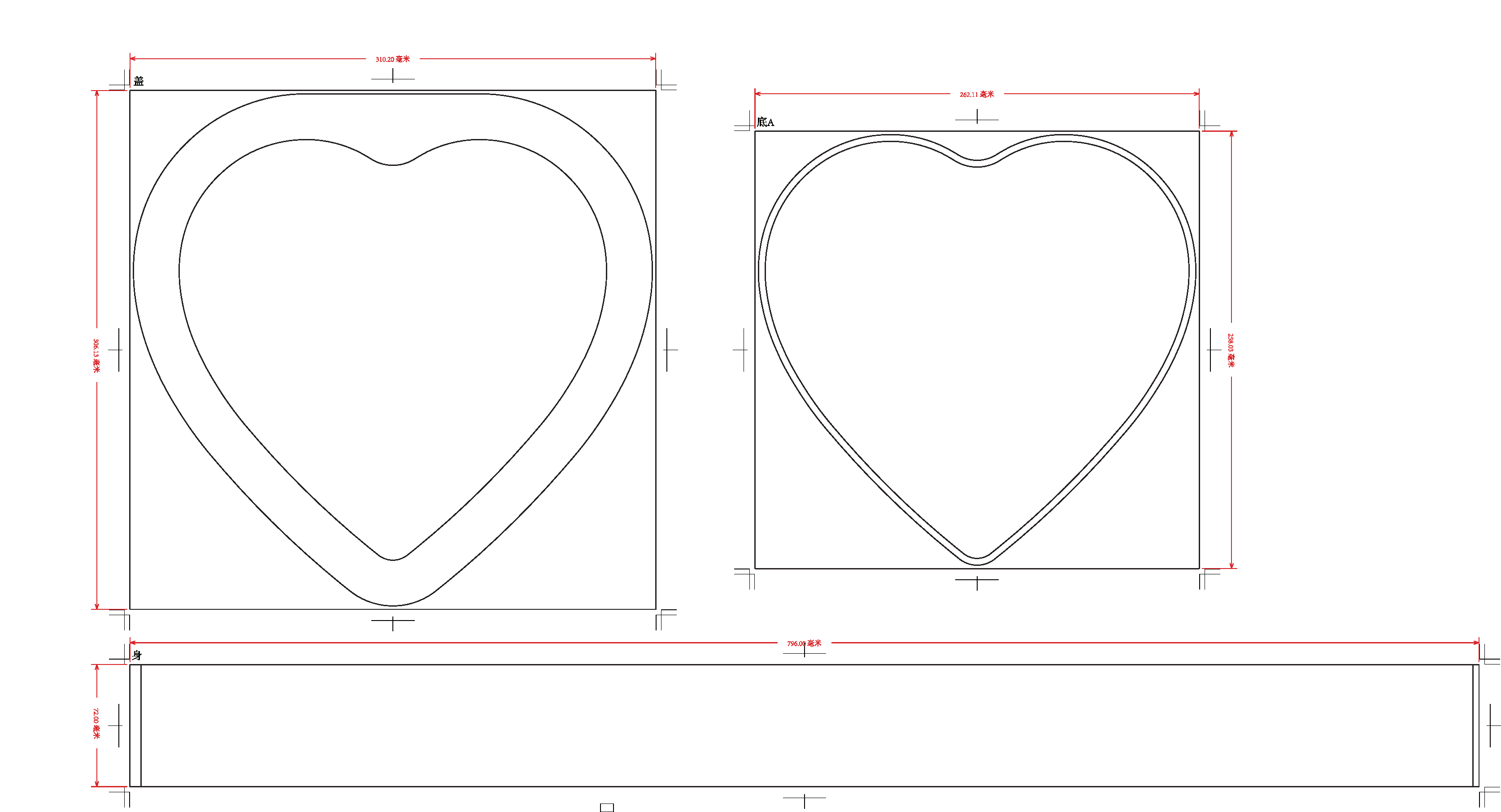

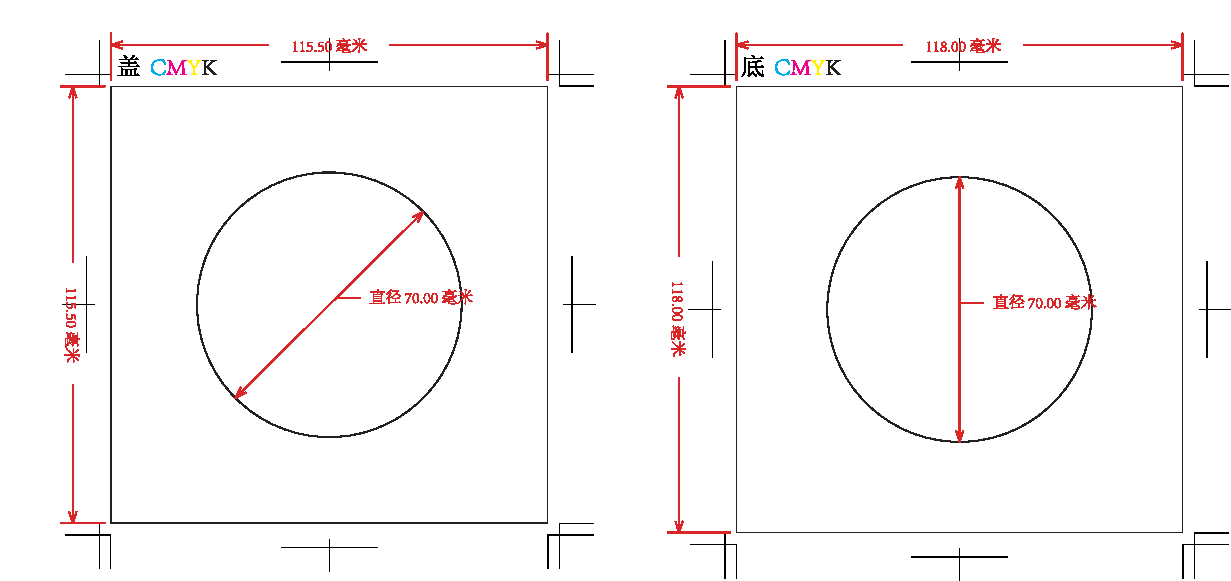

Depending on customer requirements, we can offer a wide range of customised surface finishing options, including 3D engraving and flat engraving. In addition, we can also choose four-colour or spot-colour printing on one or both sides according to customer requirements, and offer a customised service for external over-varnishing or matt varnishing. For the interior, customers can choose between gold or clear varnish and can choose different materials for the inner tray, such as flock, PVC and PET, depending on the product requirements. These personalised solutions are designed to enhance the overall effect and appeal of the product. In short, we can offer a customised combination of production and printing process services to suit the characteristics and structure of our customers' products.

The choice of printing ink is a crucial part of the manufacturing process for tinplate packaging. The tinplate surface printing inks used by our company are all environmentally friendly and meet food grade standards, allowing direct contact with food and are harmless to human health.

These printing inks are made from imported environmentally friendly inks with high printing effect and colour stability. Compared to traditional inks, they have better heat and light resistance and are less likely to fade, flake and pollute the environment during use. In addition, these environmentally friendly printing inks also have better adhesion and durability, ensuring that the packaging is less likely to be damaged during transportation, storage and distribution.

Our company has a production base of 26,600 square metres, equipped with more than 300 high standard presses and 10 fully automatic can making lines, these machines have excellent production capacity and can meet the needs of large scale production. Our average monthly production capacity of up to 5 million cans demonstrates our strength and capability in the tinplate production field.

In order to guarantee the quality and quality of our tinplates, we have more than 10 years of experience in the production of the industry and have gathered more than 300 skilled staff. They are professionally trained and practised and have the production experience and technical skills to ensure the quality and production efficiency of our tinplate products.

Our company is actively expanding into domestic and international markets and has established long-term and stable relationships with over 5,000 cooperative customers. We are constantly pursuing technological innovation and improving production efficiency in order to better meet our customers' needs and expectations.

Our company has a wide range of expertise and technical experience in the field of tinplate production. Our team of professionals will continue to strive to provide better products and services to our customers and strive to be the industry leader.

Our extraordinary achievements are due to the focus, guided by technology and based on technology, Tien-Yi continues to develop and innovate, with a single-minded focus on building fast, safe and stable products and services for our customers.

In addition to our professional production and technical staff, we also have a professional inspection team. By implementing IQC/PQC/FQC and SPC control on our products, fully implementing the company's TQM management, and with the help of advanced inspection equipment and scientific inspection standards developed, we provide our customers with high quality products and services, providing the strongest guarantee for customer satisfaction.